Continuous Insulation Panel Production Line of the PU and phenolic aldehyde surface has diversified and multifunctional production characteristics, which may produce products with different specifications such as PU, PF, PIR, etc.

The surface material may be aluminum foil, colored steel, cement base cloth, kraft paper, non-woven fabrics, etc.

The products are widely applied to such occasions as construction, decoration, pipeline ventilation, subway construction, etc.

The of soft layer insulation board is able to continuously and efficiently produce high-quality PU and Phenolic insulation boards.

We spare no efforts to improve our product quality and technological reliability by employing the most cutting-edge and the most reliable support and processes to make our products highly reliable and endurable. As a result, the of our soft layer insulation panels is highlighted by many perfect qualities. It is the core idea in Sinowa's product roadmap to surpass our competitors in terms of design philosophy, manufacture methods and service level, going for excellence and leading position and making constant improvement on our products and services, which is also our core value system to create efficiency and convenience for our customers.

Well-grounded on our solid strength as a renowned large-scale enterprise, Sinowa has a high starting point in developing industrial assembly lines.

Based on the advanced science and technology introduced from within and without the country and supported by a great number of first-grade parts and components from the home and aboard, these assembly lines have a high-level configuration of supporting products in terms of machinery, electrical control, hydraulic pressure, automatic measurement and tracking, and so on.

This is a strong proof of our product’s reliable quality and high efficiency.

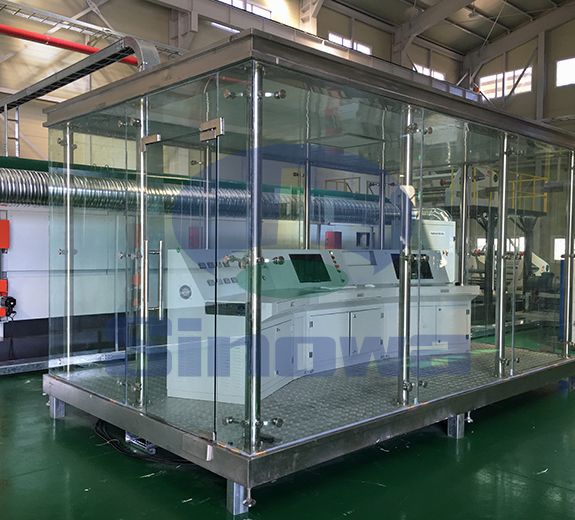

The first-class appearance design and excellent energy saving measures make it unnecessary for customers to additionally construct the heat preservation and isolation room for production around the clock throughout the year, so that the customers may save lots of resources and costs.

Modularized standard design and important parts machined with CNC machine tool make the production line have excellent quality assurance. Dependence on the man-made factors is eliminated. The operation is precision, with the highest operation speed of 30m/min. The has the world-class production efficiency.

The high performance and reliable multicomponent cyclopentane foaming technology and equipment of Sinowa may be also applied to the foaming process of the phenolic aldehyde board. Therefore, our customers may not only freely adjust the foaming matching according to the raw material, but also save lots of costs. Moreover, they are of significance for environmental protection.

Sinowa's industrial of insulation panels is distinguished by its impressive performance of energy conservation. In each high point of energy consumption throughout the entire pu sandwich panel line are implemented corresponding measures to considerably lower the consumption level.

For example, the body of the lamination belt conveyer is covered with insulation panels in very reasonable structures, which doesn’t blemish the overall outlook but greatly increases the insulation performance.

The entire is constantly optimized and improved so that the consumption of each power source is significantly reduced. The motor power of our lamination conveying system is only 3.0 kw, about 50% less than those of the same kind.

All in all, the energy consumption of the whole sandwich panel line equals 40% or even less of the equivalent lines in the market.

The of Sinowa adopts the most advanced concepts in the world to realize the modularized design with all the parts bolted together rather than welded.

In standardized production, the parts can be dismantled and exchanged, so the production cycle is drastically shortened and the maintenance becomes by far easier.

Through finite element analysis, the equipment design is greatly optimized to realize modularization, digitization, and weight-minimalization.

| PRODUCTION TYPE | PU | PIR | PHENOLIC | |||

|---|---|---|---|---|---|---|

| PRODUCTION USE | INSULATION PANEL | DOCORATIVE PANEL | ||||

| SURFACE OF SHEET | ALUMINUM FOIL | NON-WOVEN FABRIC | PAPER | NAKED | ||

| PRODUCT THICKNESS | 10m--- 200mm | |||||

| PRODUCTION SPEED | 3.0m---25m |

|---|---|

| FOAMING METHOD | TWO OR MULTI COMPONENTS FOAMING |

| FOAMING AGENT | PENTANE OR 141B |

| LENGTH OF LINE | 45m—100m CUSTOMER OPTIONAL |

Sinowa is a well-known manufacturer and technical service provider of high-end polyurethane insulation board production lines and various high-performance cold roll forming machine in China. Our main products include polyurethane double-sided color steel sandwich panel production line, polyurethane and phenolic soft facing insulation panel production line and high-efficiency roll forming machines.

Sinowa has invested outstanding efforts in color steel composite phenolic panel processing production line, This is why our products are more efficiency, quality, automatic control technology, environmental protection, energy consumption indicators and the appearance and safety protection are comprehensively leading, Some subversive design changes in many major technical points,these major innovations make our products excellent in price/performance and user experience.

Sinowa is committed to the development and manufacturing of high-end and high-efficiency color steel composite phenolic panel processing production line. Our sandwich panel production lines are leading the way in efficiency, automatic control, human-computer interaction, environmental protection and energy consumption. Using system integration and bus control technology, it realizes the automatic integrated linkage control of the entire production line, and can achieve remote interactive communication, which has the world-class level and a comprehensive leading high-performance production line in the market.

?Color Steel Composite Phenolic Panel Processing Production Line? Post Date:2023/9/14

URL: http://www.yczgjl.com/en/blog/color-steel-composite-phenolic-panel-processing-production-line.html